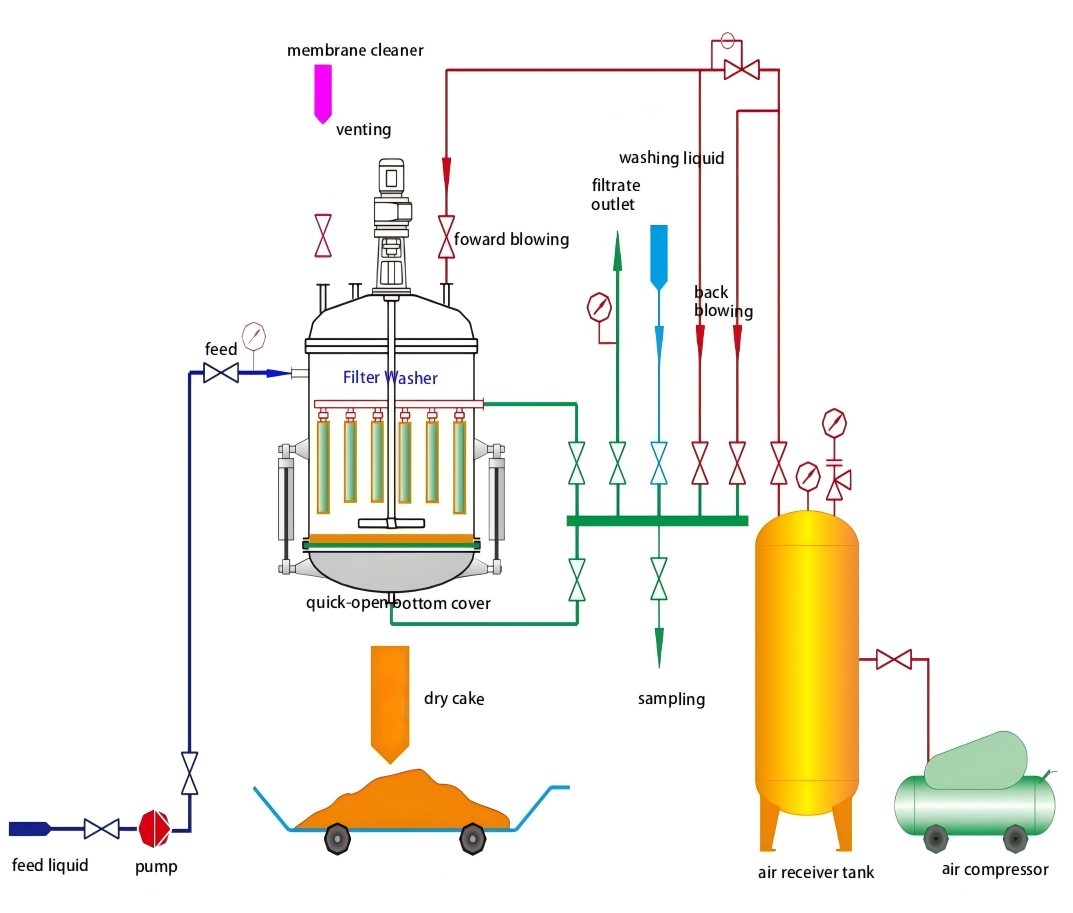

The PGPX Filter Washer is purpose-built for slurry washing, filtration, and pressure drying where high cake dryness and strict batch separation are critical. Featuring an integrated agitator and quick-opening bottom discharge with microporous elements, PGPX achieves residue-free discharge while delivering superior washing performance. It is widely adopted in fine chemicals, pharmaceutical APIs, food additives, and specialty powders, where product quality and strict process control are essential.

Integrated agitator provides uniform washing, reducing wash solvent consumption while enhancing impurity removal.

Guarantees residue-free discharge, preventing cross-batch contamination.

Positive-pressure drying and controlled blow cycles achieve higher cake dryness than conventional methods.

Single-unit area up to 200 m²; quick-opening door diameter up to 2 m for efficient cake discharge.

Wetted parts available in plastic lining, stainless steel, or titanium to meet various slurry conditions.

Sealed filtration, agitation washing, pressure drying, cover-opening discharge, and multi-unit synchronization.

High cake dryness for downstream handling: Combines washing and pressure drying to deliver cakes with low moisture content, reducing downstream drying costs and improving transport efficiency.

Residue-free discharge: Quick-opening bottom with microporous design ensures complete liquid removal, eliminating cross-batch risks in regulated industries.

Uniform washing efficiency: Agitator ensures wash liquid penetrates the cake evenly, producing high-purity crystalline products with reduced solvent use.

Precision with ultrafine powders: Processes sensitive powders while achieving high dryness and preserving particle integrity, ideal for specialty chemicals and APIs.

Trusted in high-value production: Extensively used in fine chemicals, APIs, food additives, and specialty powders, where strict batch control and dry cake handling are required.

Dongou MF participated in the 23rd Pharma Asia 2025, held from December 2–4 in Karachi, Pakistan—Asia’s major exhibitions for pharmaceutical

KHIMIA 2025 brought together companies from across the global chemical and process industries, and DongouMF was pleased to participate in

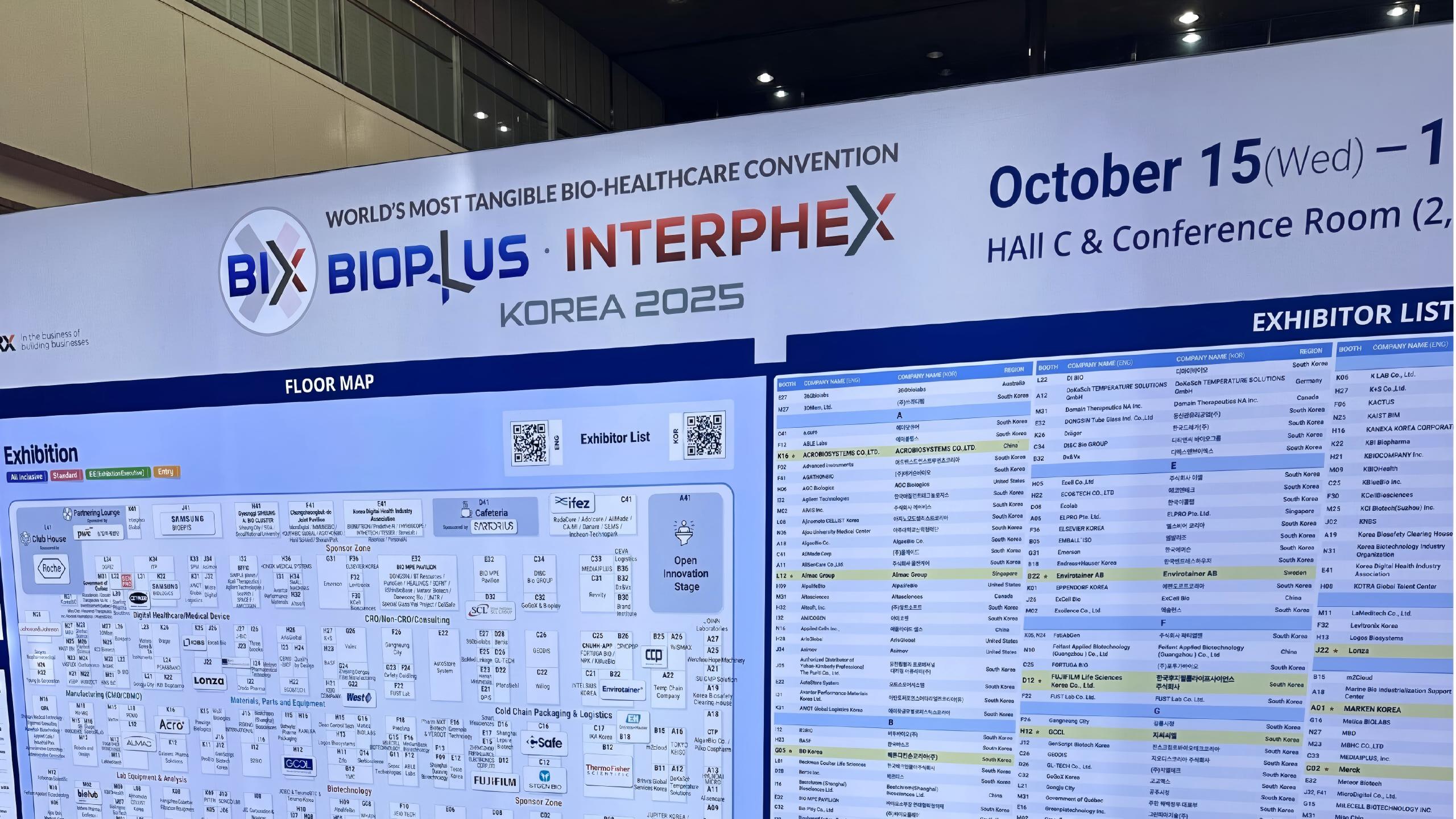

Seoul, Korea — November 2025 At BIOPLUS-INTERPHEX Korea 2025 (BIX 2025), Dongou MF showcased its advanced polymer-based microfiltration and solid–liquid