Introduction

Coal chemical processes involve high-load, high-viscosity, and chemically aggressive streams that place heavy demands on filtration equipment. Stable, fouling-resistant solid–liquid separation is essential for controlling suspended solids, protecting downstream units, and improving resource recovery.

Dongou MF’s polymer-based microfiltration modules are engineered for these severe coal-derived media—ultra-fine coal powder, emulsified oil, phenols, tar residues, sulfur-rich slurries, and corrosion particles. With stable flux, high chemical compatibility, and long operating cycles, our systems help plants reduce unplanned downtime, maintain process stability, and improve the clarity and consistency of circulating and wastewater streams.

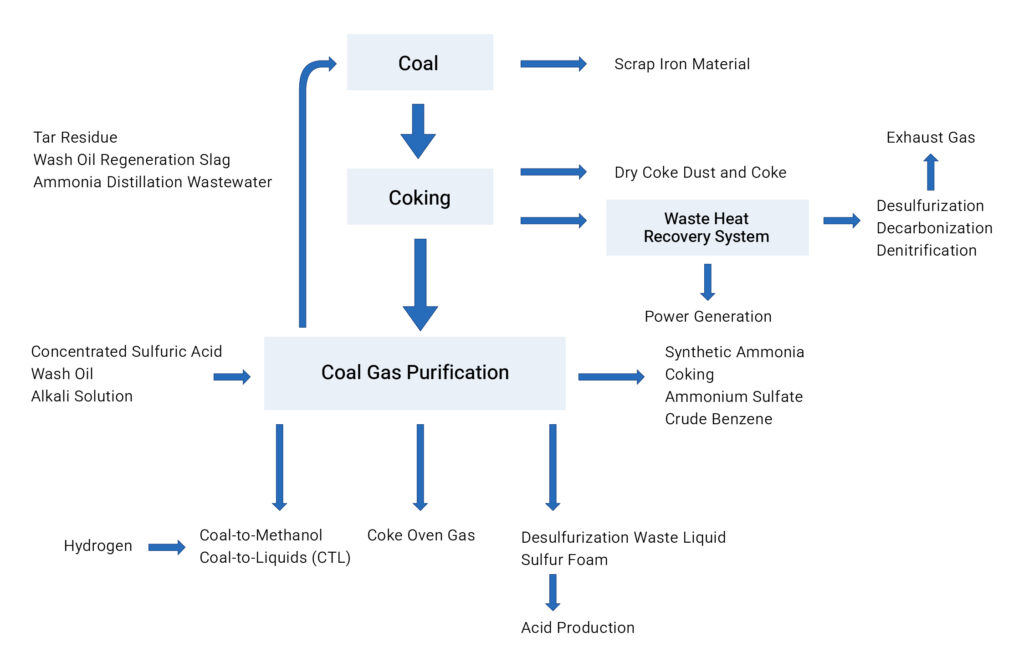

Where Filtration Fits in the Coal Chemical Process

Filtration is integrated at key nodes, including CO₂ absorption in synthetic ammonia, CTL wastewater polishing, and wet desulfurization sulfur-foam concentration.

Integrated Solutions for High-Load Coal Chemical Streams

1. Synthetic Ammonia: Microfiltration for Hot Potassium Carbonate (HPC) Semi-Lean Solution

HPC semi-lean solutions progressively accumulate fines, corrosion particles, degraded glycine, and resin by-products. These impurities increase absorber foaming, raise energy consumption in regeneration, and accelerate equipment fouling.

Dongou Microfiltration Solutions

Our corrosion-resistant polymer microfiltration modules (temperature resistance up to 260°C, fully compatible with acids, alkalis, and salts) are designed to:

- Continuously remove fine suspended solids from circulating semi-lean solution

- Reduce fouling in heat exchangers and absorber towers

- Maintain stable clarity with uninterrupted operations

- Support multi-cycle regeneration (backflush + chemical recovery)

Industry Application

Dongou systems have been deployed in synthetic ammonia units treating aminoacetic acid–HPC semi-lean solutions, enabling stable decarbonization performance and extending solution life.

2. Coal-to-Liquids (CTL): Microfiltration for High-COD, Ultra-Fine Wastewater

CTL wastewater contains oil, phenols, tar, and ultra-fine coal particles (D50 <1 μm). These characteristics overwhelm conventional sedimentation and impose high loads on downstream biological treatment.

Dongou Microfiltration Solution

Our systems provide:

- High-throughput separation of ultra-fine solids

- Low-turbidity permeate suitable for reuse or polishing

- Full chemical resistance for complex coal-derived wastewater

- Sealed, automated modules with PLC control, over-pressure protection, and safety interlocks

Representative Industrial Data

Linkou Power Plant (Taiwan) – Coal Yard Runoff

- Particle size: D50 = 0.0691 μm

- Capacity: 100 t/h per unit

- Final effluent: SS <1 ppm

This demonstrates Dongou’s capability in long-term filtration of ultra-fine, high-COD particulate wastewater.

3. Wet Desulfurization: Sulfur Foam Concentration for Sulfuric Acid Production

Wet FGD units generate dilute sulfur foam mixed with dispersed fine solids. Traditional methods such as plate-and-frame filter presses or centrifuges often face challenges: low automation, high energy consumption, long process flows, and non-sealed operation. Efficient microfiltration is essential to recover sulfur, stabilize downstream production, and simplify process handling.

Dongou’s sealed microfiltration systems offer:

- Continuous concentration of sulfur foam with regulated solids content (10–30%) suitable for downstream sulfuric acid reaction

- Full chemical compatibility with acidic desulfurization streams

- High automation: multi-module, high-frequency backflush, and in-tank dispersion for consistent solids handling

- Long filter life: filter cartridges operate for 2+ years while maintaining process compliance

- Cleaner, closed-loop operation with minimal manual intervention

Industry Deployments

Deployed across major domestic coking and steel-chemical plants, including:

This fully automated system delivers process-ready concentrated slurry while replacing traditional press or centrifuge methods.

Why Dongou Performs in Harsh Coal-Chemical Conditions

Dongou’s polymer microfiltration modules are built to withstand severe process environments:

- Temperature resistance: up to 260°C

- Full corrosion resistance: acids / alkalis / salts

- Backflushable + chemical recoverable for long service life

- High throughput for high-solids or ultra-fine applications

- Sealed system + PLC automation for safe, stable, low-maintenance operation

- Compatible with multiple layout configurations (side-inlet, top-inlet, bypass integration)

These engineering features ensure long-term stability across synthetic ammonia, CTL wastewater, and wet-desulfurization applications.

Conclusion

As coal chemical plants pursue higher reliability, lower emissions, and better resource efficiency, DongouMF provides field-proven microfiltration systems that stabilize HPC solutions, treat high-COD CTL wastewater, and concentrate sulfur foam—supported by tailored engineering consultation for your process conditions. Contact our team today to discuss your application and receive a customized solution.