Intro

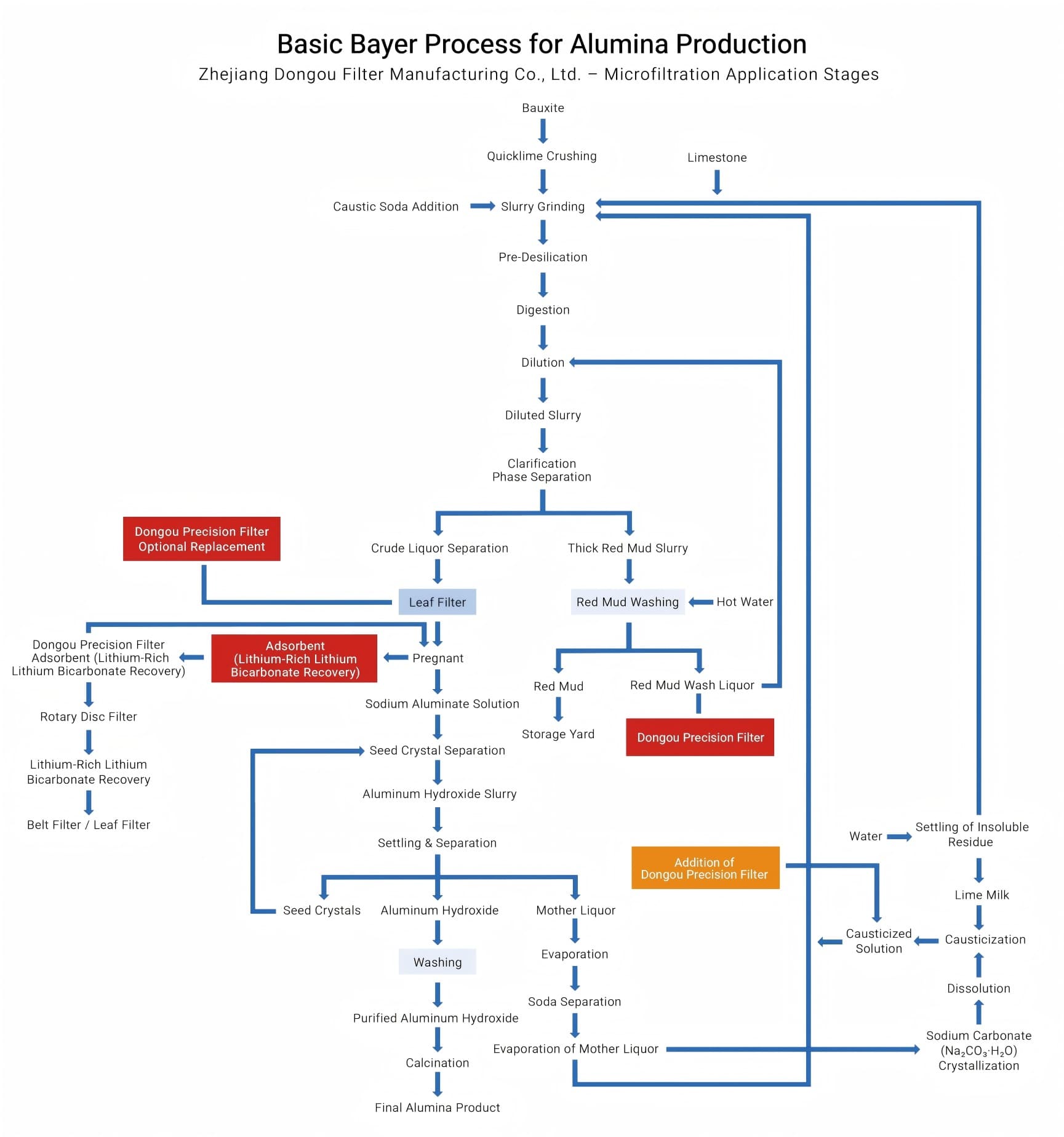

In Bayer alumina production, precise solid-liquid separation is essential for product quality, chemical efficiency, and operational stability. Traditional leaf filters often suffer from cloth wear, tearing, and high labor requirements, making reliable filtration a challenge.

Dongou Microfiltration systems provide high-precision, durable, and regenerable filtration solutions for each stage—including red mud washing, liquor clarification, and aluminum hydroxide separation—also supporting lithium recovery to enhance yield and economic efficiency.

Stage 1: Red Mud Washing & Separation

Challenge:

Post-digestion red mud slurry is viscous, abrasive, and uneven. Inefficient separation of entrained sodium aluminate causes alumina and caustic soda losses, increasing downstream processing costs.

Dongou Solution:

- High-Throughput Filtration Systems: Designed for effective flow and particle separation, our microporous filtration tubes ensure reliable red mud washing and maximize recovery of valuable sodium aluminate.

- Durable & Chemical-Resistant: Filters withstand high temperatures (up to 110°C), strong alkalinity, and abrasive solids for long-term stable operation.

- Continuous Stirring & Spraying: Inverted filtration tubes with internal stirring prevent cake buildup, ensuring uniform washing and preventing clogging.

- Minimized Reagent Loss: Efficient filtration preserves sodium aluminate solution, reducing soda consumption and improving plant economics.

Stage 2: Green/Spent Liquor Filtration & Lithium Adsorbent Separation

Challenge:

Pregnant or spent liquor contains colloidal silica, fine solids, and lithium-enriched aluminum hydroxide adsorbents. Their breakthrough can compromise crystal growth and reduce lithium recovery. Traditional leaf filters are prone to cloth wear, perforation, and high labor intensity.

Dongou Solution:

- 0.2 μm Precision Microfilters: Effectively separate fine solids and lithium adsorbents while maintaining high liquor clarity.

- Durable Filtration Tubes: Sintered high molecular weight polyethylene tubes resist strong alkali and high-temperature conditions, with long service life.

- Integrated Spraying & Continuous Stirring: Upper and lower filtration tubes work together, continuously washing filter surfaces and preventing filter cake accumulation.

- Regeneration Capability: Filters can be periodically chemically regenerated under strong alkali conditions, ensuring consistent performance with minimal downtime.

Stage 3: Aluminum Trihydrate Classification & Washing

Challenge:

Post-precipitation slurry requires seed separation and washing. Inefficient separation leads to uneven particle size, high residual soda, increased evaporation energy, and lower lithium recovery efficiency.

Dongou Solution:

- Custom-Configured Precision Microfilters: Separate fine seed from coarse product, optimizing aluminum hydroxide crystal growth and lithium adsorbent recovery.

- Efficient Washing & Recovery: Continuous filter operation with counter-current washing reduces water and chemical consumption, lowering operational costs.

- Mechanical Robustness: Equipment tolerates cyclic loading and abrasive solids, ensuring long-term reliability.

Stage 4: Spent Liquor Treatment & Purification

Challenge:

Circulating spent liquor accumulates impurities such as oxalates, sulfates, and fine solids, causing scaling in evaporators and reducing digestion efficiency.

Dongou Solution:

- Side-Stream Microfiltration: Continuous removal of sub-micron impurities keeps circulating liquor clean, protecting evaporators and overall process stability.

- Chemical and Physical Durability: Filtration tubes resist strong alkali, acids, and salts.

- Improved Plant Stability: Reduces scaling, extends maintenance cycles, and enhances thermal efficiency across the evaporation system.

Innovation Highlights

- High molecular weight polyethylene sintered filtration tubes.

- Filter elements withstand high temperature (110°C) and strong alkalinity.

- Inverted filtration tubes with internal stirring prevent cake buildup.

- Tubes withstand high-frequency, high-pressure air-liquid backflushing.

- Periodic strong-alkali chemical regeneration extends filter life.

- Long-life, stable, high-precision, high-throughput filtration.

Why Dongou Filters?

Custom Engineering: Lab sample analysis and pilot-scale testing ensure the optimal filter selection for each Bayer process stage and lithium recovery application.

Integrated Systems: Skid-mounted, PLC-controlled units with piping and platforms enable rapid installation and seamless commissioning.

Sustainable Productivity: Precision filtration across all process stages reduces chemical consumption, enhances product quality, and ensures operational stability.

Contact us today to request a customized purification network for your Bayer process alumina production.