The Core Issue: A Bottleneck Hidden in Plain Sight

The washing stage of iron phosphate precursors directly determines final cathode purity.

Yet many plants still rely on open plate and frame filter presses, originally designed for far less demanding chemical processes.

The result is inconsistent washing, residual impurities, and a bottleneck that quietly limits scalability and market access.

1. The Direct Link: Washing Efficiency = Battery Performance

In industrial practice, washing performance is commonly measured by the conductivity of the filter cake liquid, which reflects residual sulfate and ammonium ions.

Poor washing allows these impurities to carry into the final LFP material, degrading crystal structure and increasing internal resistance.

Why this matters:

- Many operations struggle to stay below 500 µS/cm.

- Premium LFP products increasingly require much lower conductivity levels.

- Your washing capability directly impacts your product grade, price, and market access.

The True Cost of Using a Plate and Frame Filter Press

The traditional plate and frame filter press imposes a triple burden that erodes your bottom line. The core inefficiencies are summarized below:

Table: The Triple Cost of the Plate and Frame Filter Press

| Cost Dimension | Core Problem | Impact on Your Business |

| Quality & Product Value | Cloth leakage, uneven washing, high and variable conductivity. | Poor batch consistency, failure to meet premium specs, product commoditization, inability to command price premiums. |

| Operations & Environment | Open process, VOC emissions, chronic leaks, poor workplace environment. | Challenges in worker safety/retention, high compliance risk, failure in customer ESG audits, additional waste treatment costs. |

| Efficiency & Scalability | Labor-intensive, batch-locked, high water/energy use, low automation. | Becomes a bottleneck during ramp-up, high OPEX, incompatible with modern, data-driven “smart factory” flows. |

3. The Strategic Upgrade: From Bottleneck to Advantage

This bottleneck, however, is not a fixed cost. Upgrading to a next-generation precision microporous filtration system turns this “Triple Cost Center” into a “Triple Strategic Advantage”: enabling a leap in product purity and consistency, creating an automatable and scalable modern process, and fulfilling the most stringent ESG and sustainable manufacturing requirements.

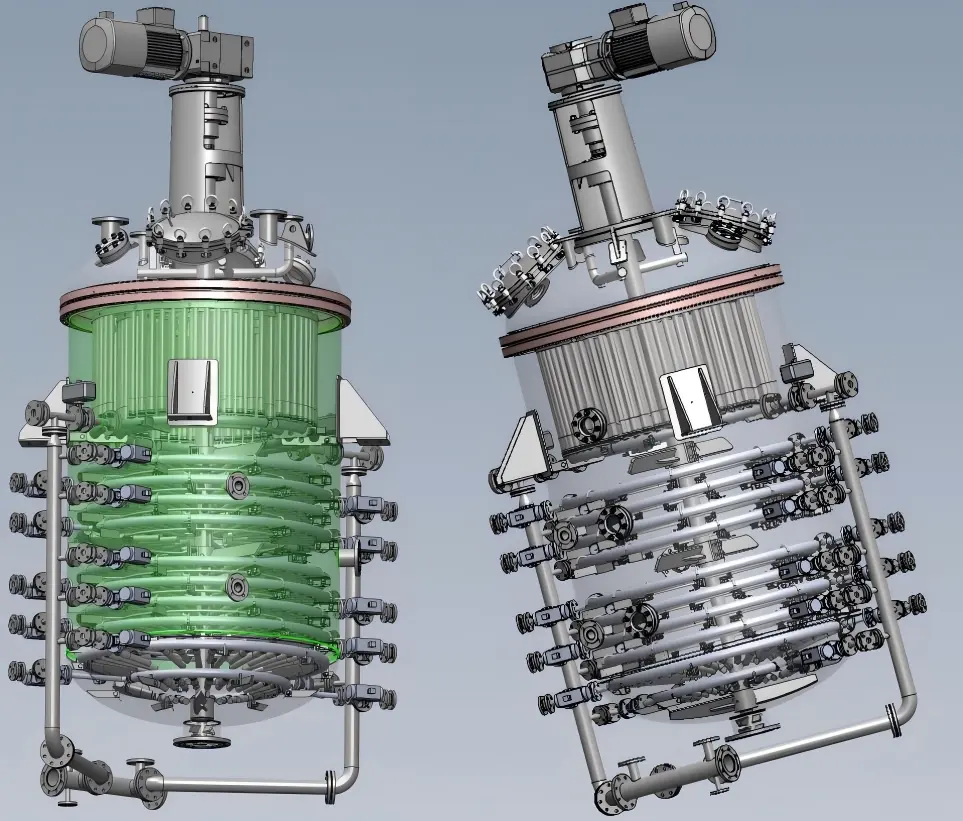

The Solution in Principle: Closed-Loop Precision Filtration

The path forward is adopted by leading producers: integrated systems with precision sintered microporous (PEF) filters. This approach directly counters the table above:

- Guaranteed Quality: Hermetic sealing ensures zero leakage and consistent, high-purity output.

- Efficient Washing: Programmable, uniform washing eliminates dead zones, achieving reliably low conductivity.

- Automated Operation: Full PLC control enables 24/7 operation, data traceability, and a clear path to a “dark factory” for this unit operation.

What’s Next: Transform Insights into Action

Understanding the problem is the first step. The next is to explore a proven solution tailored to your operation.

See how industry leaders are solving this. We document the complete journey—from initial pilot data to full-scale implementation—in detailed case studies.

Ready to assess your specific scenario?