For plant managers and EHS officers, achieving operational safety and environmental goals often feels like a balancing act against cost and efficiency. But what if the most effective way to reduce exposure, slash waste, and mitigate risk was not an added control, but the core design of the process itself? This is the fundamental shift offered by moving from open, batch operations to a fully integrated, closed-loop system.

Where Do Risks Hide in a Fragmented Process?

Traditional batch processing, with its manual transfers and open equipment, creates multiple points of failure in chemical plant safety:

- Exposure Points: Each filter cake discharge, centrifuge unload, or reactor transfer risks operator contact during hazardous chemical handling.

- Fugitive Emissions: Open vessels and frequent connections are primary sources of VOC emissions and product loss.

- Waste Multipliers: Inefficient separation means lower yields and more contaminated solvent or solid waste for costly disposal.

Engineered Safety: The Integrated Advantage

The All-in-One Reactor Filter addresses these process safety issues through its core design principles:

Containment as the First Defense

The entire process sequence occurs within a single, pressure-rated sealed vessel, a fundamental containment strategy. This eliminates the hazardous open transfer of materials. The key innovation is the patented bubble transport system, which enables complete, automated cake discharge without any manual intervention, virtually eliminating a major exposure risk.

Efficiency as Pollution Prevention

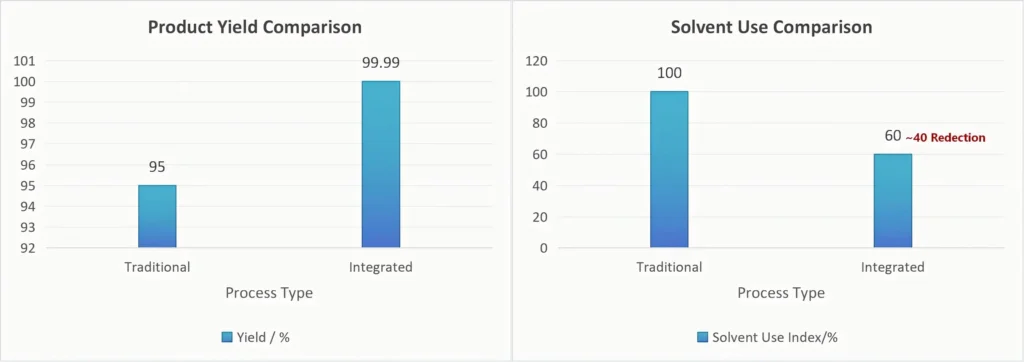

Superior performance is inherently greener and core to sustainable chemical manufacturing. By achieving ≥99.99% product recovery, the system drastically reduces the mass of valuable product lost to waste streams. Furthermore, the efficient counter-current “back wash” can reduce solvent consumption for cleaning by 30-50%, directly minimizing the volume of waste requiring treatment.

Reliability through Intelligent Design

The modular, zoned filtration design allows for operational isolation, preventing a local issue from causing a full shutdown. This enhances overall plant stability and reduces emergency response scenarios.

What is the Strategic Upside? From Cost Center to Value Driver

Adopting this integrated approach—a form of process intensification—transforms safety and sustainability into strategic advantages for ESG manufacturing:

- Inherent Safety: It embodies Minimization, reducing hazardous material inventory at the source.

- ESG & Lifecycle Benefits: Direct reductions in solvent, waste, and energy use improve sustainability metrics and product footprint.

- Economic Co-Benefit: Savings from higher yield, lower waste handling, and reduced downtime make the investment financially compelling, aligning profit with safety.

Rethink the Process, Unlock Platform Potential

The journey begins with a fundamental question: “Where can we eliminate the hazard, instead of just managing it?”

While demonstrated in glyphosate production, the integrated “All-in-One” philosophy addresses a universal challenge: any process requiring precise, immediate solid-liquid separation after reaction. This makes it an adaptable platform, not just a single machine. The proven core—modular zoning, sealed automation, and precision filtration—can be customized for different chemistries, pressures, and materials across pharmaceuticals, fine chemicals, and metal recovery.

We have already adapted this platform to challenges like catalyst recovery and ultrafine powder washing. The question is no longer if it applies, but how it can transform your specific process.