For decades, glyphosate production has been defined by a fragmented process: react in one vessel, then transfer slurry to another for separation. This paradigm creates inherent bottlenecks in continuous manufacturing process efficiency, product recovery, and operational safety.

At Dongou Microfiltration, we approached this not as a question of improving individual units, but of systematic chemical process design. The result is a reimagined integrated reaction and filtration system. This article outlines the core design philosophy that transforms the traditional batch sequence into a seamless, automated continuous manufacturing system.

Core Engineering Decision 1: From Horizontal Transfer to Vertical Functional Zoning

The Challenge: How to integrate reaction and filtration in one vessel efficiently?

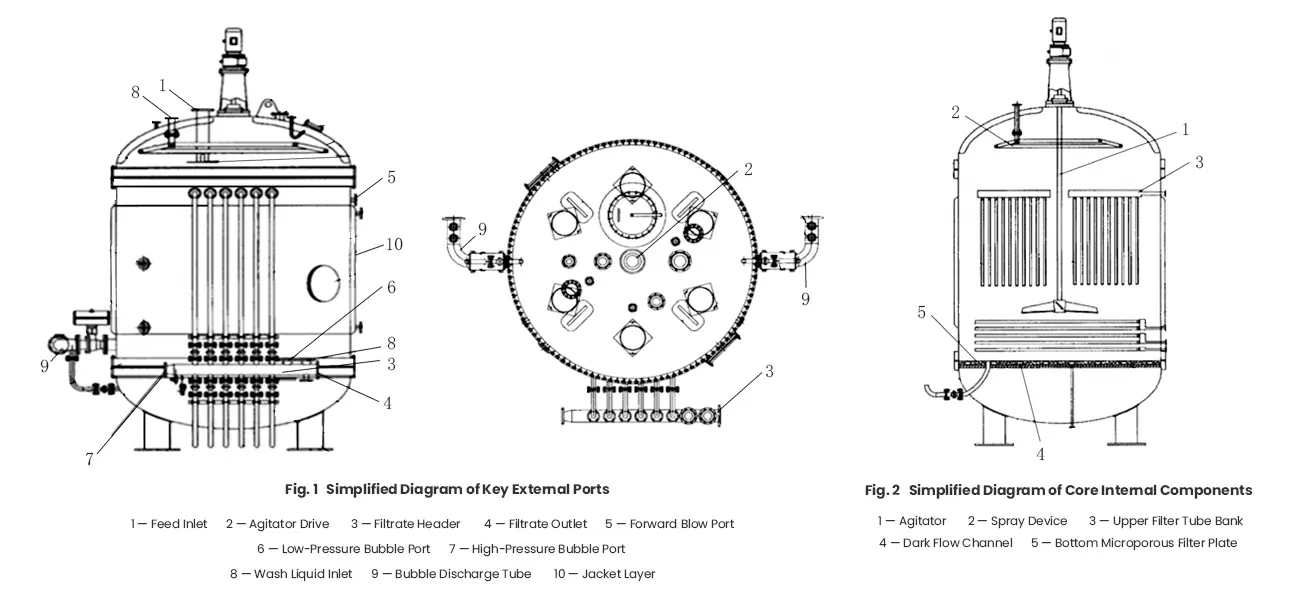

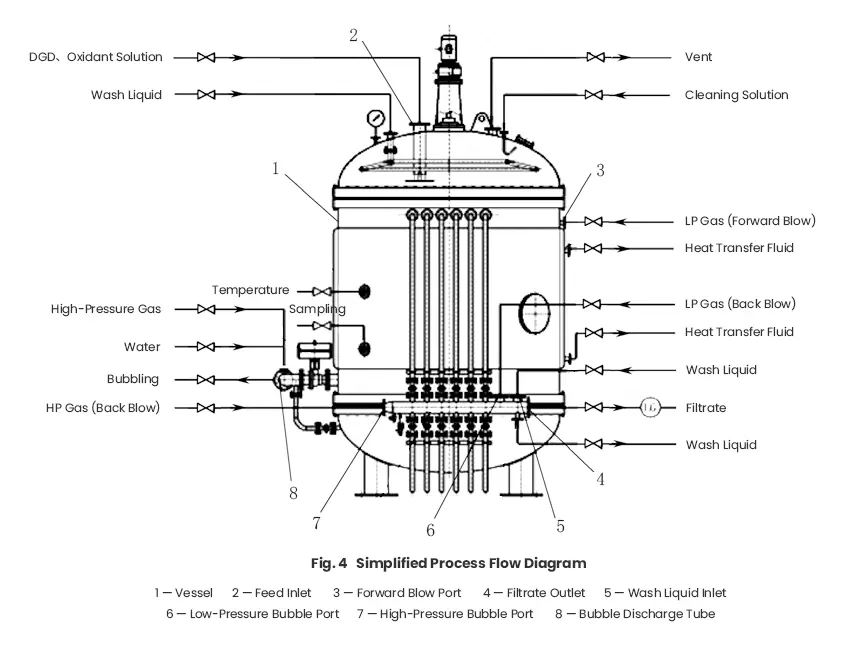

The Logic: Instead of connecting separate tanks, we applied the principle of vertical functional zoning in reactors. A single pressure vessel is internally architected into dedicated, stacked zones for agitation/reaction, precision microfiltration, in-place washing, and discharge.

The Innovation: This modular reactor design allows the process sequence—from reaction to cake formation—to proceed vertically by gravity and controlled flow without inter-stage pumping or transfer. It is the physical foundation for continuous reaction filtration integration, eliminating downtime between batches and reducing the footprint for industrial plant design.

Core Engineering Decision 2: From Disposable Elements to Regenerative, High-Precision Core

The Challenge: How to ensure precision filtration (down to 0.2μm) while withstanding years of aggressive chemical and mechanical cleaning cycles?

The Logic: A filter that clogs or degrades quickly undermines any integrated process optimization. We needed a core that combined ultra-fine pore structure with extreme durability.

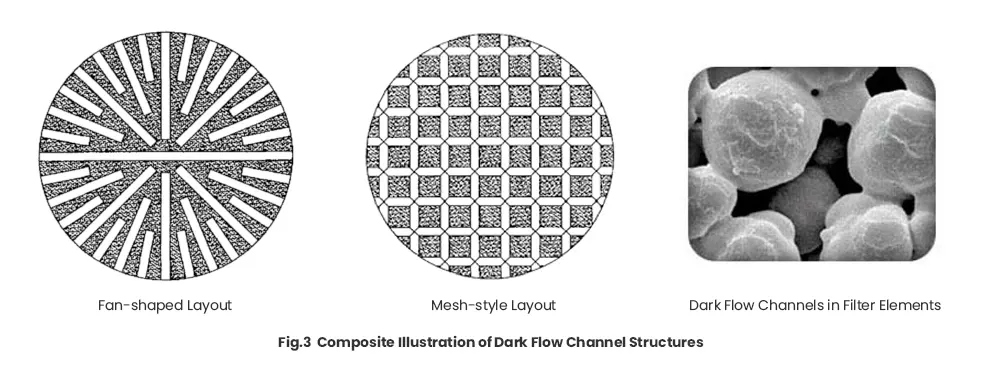

The Innovation: The patented(ZL200810184815.4) dark flow filtration channels. This engineering innovation in filtration features a network of subsurface channels within the UHMWPE filter element.

- During operation, pressure is evenly distributed, preventing premature blinding.

- During cleaning, a uniform back-pulse effortlessly dislodges the cake.

This regenerative capability is key to high product recovery and long-term stability in industrial chemical filtration systems.

Core Engineering Decision 3: From Manual Batch Handling to Sealed, Automated Cycling

The Challenge: How to automate glyphosate cake washing and drying and achieve clean discharge in a closed system filtration unit?

The Logic: True process optimization and automation requires replacing all manual interventions with a deterministic, in-situ sequence.

The Innovation: A proprietary “Forward Blow – Back Blow – Back Wash – Bubble Transport” cycle. After filtration, gases and wash liquids are automated for in place washing & drying. The final breakthrough is bubble assisted cake transport: introducing gas to fluidize the solid cake, enabling it to be pumped out of the vessel as a slurry. This completes a full end to end process efficiency loop, reducing operator exposure in chemical plants to zero and enabling true chemical plant automation.

Conclusion: Beyond a Machine — A Deterministic Process Guarantee

The All-in-One Reactor Filter embodies our core engineering philosophy: Start with the end in mind. Every design decision is reverse-engineered from the goals of maximal yield, safety, and continuity.

We deliver not just equipment, but a complete, guaranteed process solution—including the critical process package, automated control system, and comprehensive operator training. This ensures the performance validated in our lab translates into deterministic results at your site.

If you face a solid-liquid separation challenge that seems “impossible”, the solution may not be a better component, but a process improvement. We are ready to embark on that design journey with you.