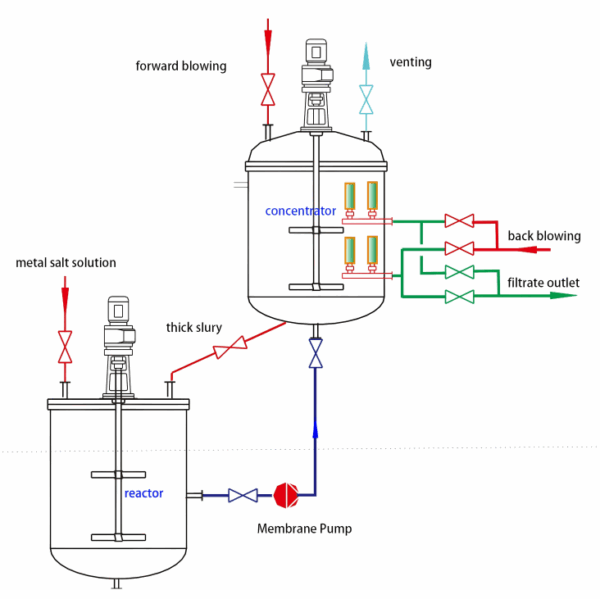

The Concentration Filter is an advanced integrated system designed for efficient chemical synthesis and particle processing applications. It seamlessly integrates with synthesis reactors to enhance reaction efficiency, achieve uniform particle size distribution (PSD), and optimize material morphology. This versatile solution supports sustainable manufacturing by minimizing waste and maximizing yield through precise control and automation.

Key advantages include:

With flexible material lining options for slurry-contact components and magnetic-impurity-free filtration, it ensures contamination-free operation. Fully automated features, such as grouped backflush, continuous cycling, and multi-point control, enable uninterrupted, high-throughput production.

Comprises main vessel, motor, reducer, transmission system, agitator, sealing mechanism, pipeline reactor, microporous filter tubes, draft tube, supports, process interfaces, piping, valves, instrumentation, PLC control system, and vacuum device.

Equipped with high-quality reducers (e.g., SEW or equivalents) and variable frequency drives for stepless speed control of the agitator, ensuring optimal mixing.

Custom paddle blades paired with a draft tube promote thorough mixing and turbulent flow, tailored to material properties and vessel volume for maximum reaction uniformity.

Fillers or dual mechanical seals to meet process requirements, preventing leaks in demanding environments.

High length-to-diameter ratio (>50) for intensive turbulent reactions; customizable with state-of-the-art domestic or international technologies.

Microporous tubes provide precise, non-magnetic filtration; integrated DCS supervisory system monitors and controls parameters like pH, flow rates (instantaneous and cumulative), and temperature via on-site, control room, and pump triple-linkage.

Reaction & Aging: Within the reactor, multi-parameter controls precisely regulate crystal nucleation and growth. Multi-stage agitation and an inverted microporous filtration layout enable fine crystals to continuously recirculate to the reaction zone. This prevents settlement and filter blockage, while promoting the formation of a narrow, consistent crystal size distribution.

Washing & Purification: High-purity water, hot water, or solvent is introduced through dedicated process lines. Thorough mixing ensures effective impurity removal, meeting stringent product purity specifications.

Concentration & Filtration: Integrated vacuum, precision microporous filtration, and automated control systems progressively concentrate the slurry to the target density. This design minimizes pressure load on the filtration unit, enhancing operational stability and lifespan.

Overall Efficiency: The system enables fully automated, continuous operation with minimal downtime. By ensuring tighter control over PSD (Particle Size Distribution) and morphology, it significantly increases product yield and quality, while reducing energy consumption and material waste.

| Parameter | Range/Value |

| Vessel Volume | 0.5–30 m³ |

| Filter Area | 0.2–40 m² |

| Filtration Precision | 0.2–10 μm |

| Vacuum Degree | -0.01 to -0.1 MPa |

| Backflush Air Pressure | 0.1–0.7 MPa |

| Corrosion-resistant Linings | SUS304 |

| SUS316L | |

| TA2 | |

| Steel-lined Titanium | |

| Steel-lined Stainless Steel | |

| Steel-lined Plastic |

Fully customizable based on your application needs

Dongou MF participated in the 23rd Pharma Asia 2025, held from December 2–4 in Karachi, Pakistan—Asia’s major exhibitions for pharmaceutical

KHIMIA 2025 brought together companies from across the global chemical and process industries, and DongouMF was pleased to participate in

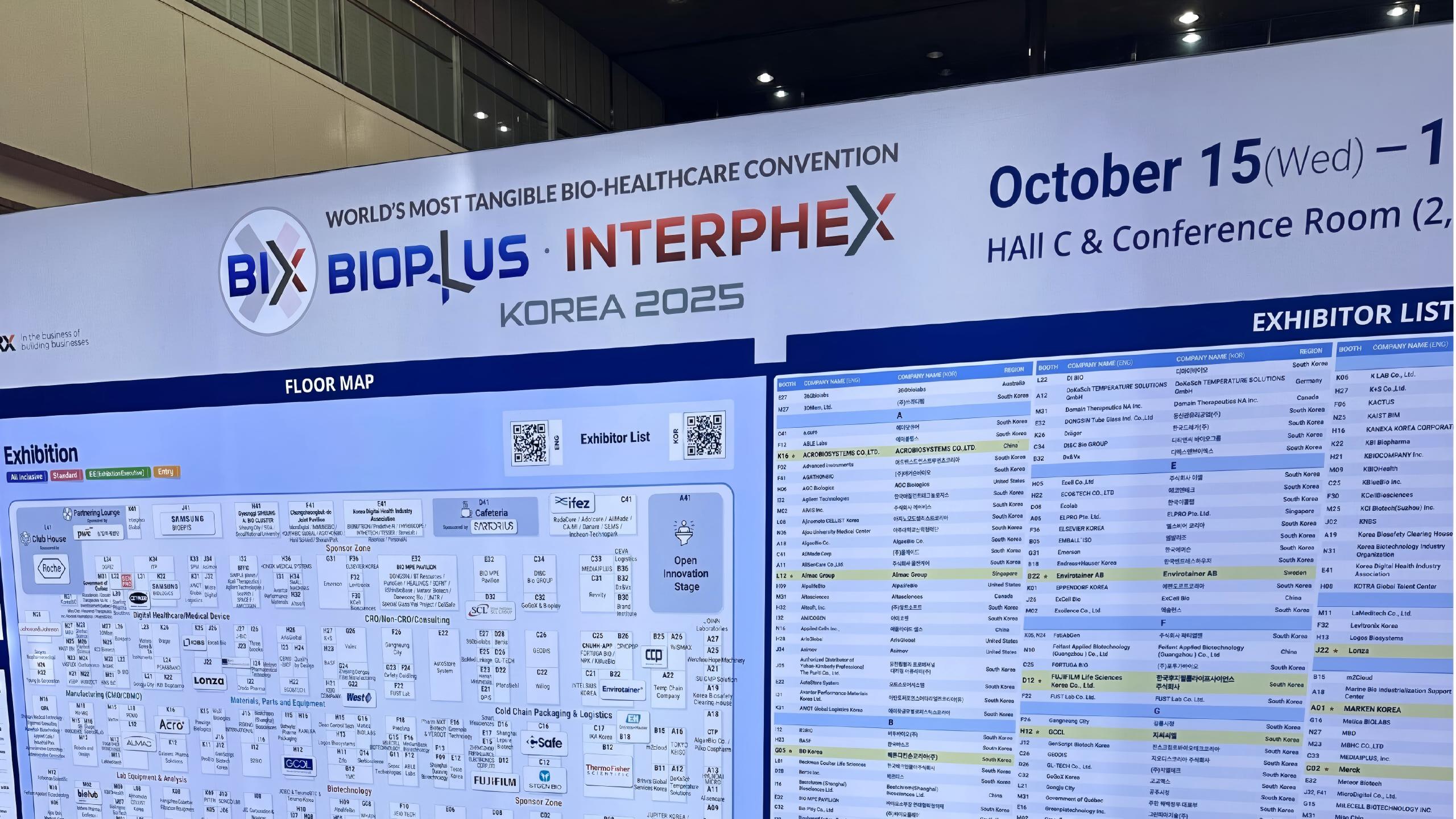

Seoul, Korea — November 2025 At BIOPLUS-INTERPHEX Korea 2025 (BIX 2025), Dongou MF showcased its advanced polymer-based microfiltration and solid–liquid