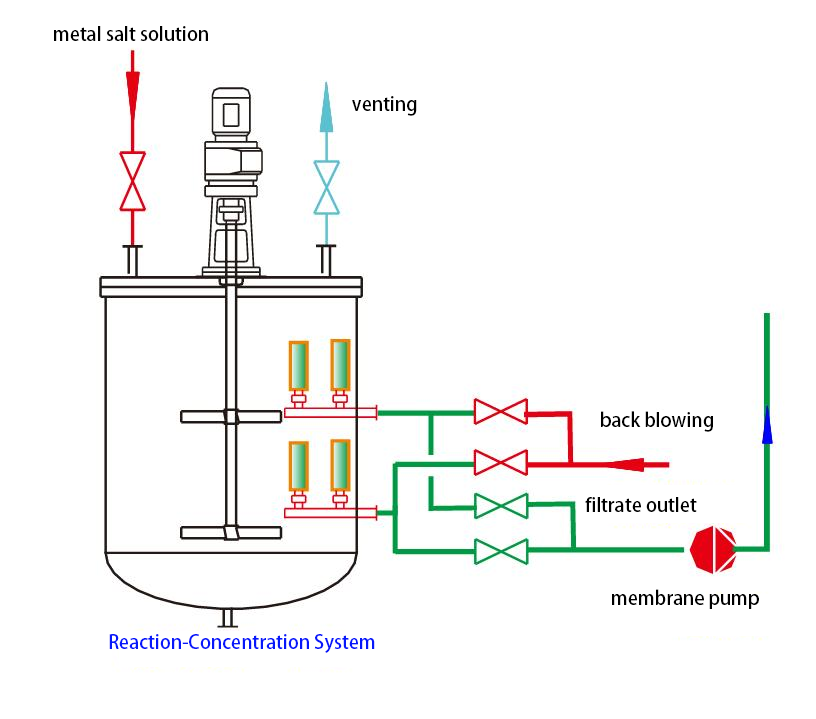

The PGFYNS is an integrated reaction and concentration unit featuring single-vessel assembly with dosing pumps for multiple raw materials (A, B, C+), slightly pressurized reaction synthesis system, agitator, regenerable microporous tubes, vacuum filtration system, and PLC/DCS controls. This integrated design reduces overall equipment and transfer requirements.

By combining reaction, feeding, and concentration processes in one system, it simplifies operations while ensuring precise control and reliable performance for demanding applications in chemical, pharmaceutical, and metallurgical industries.

The system enables a streamlined, continuous process within one unit:

Proportional multi-feed dosing into the pipeline for initial reaction, followed by 6–8 hours of draft-tube agitation for even PSD and refined morphology.

Continuous mother liquor extraction via vacuum and microporous filtration, achieving target concentration levels without process halts.

Direct in-vessel washing with added solvents or water, then pumping to downstream – shortening four standard steps to one for quicker cycles.

Results in 30% lower footprint and investment, up to 20% higher yield in multi-component synthesis, improved purity, and reduced energy/waste through stable operation.

Dongou MF participated in the 23rd Pharma Asia 2025, held from December 2–4 in Karachi, Pakistan—Asia’s major exhibitions for pharmaceutical

KHIMIA 2025 brought together companies from across the global chemical and process industries, and DongouMF was pleased to participate in

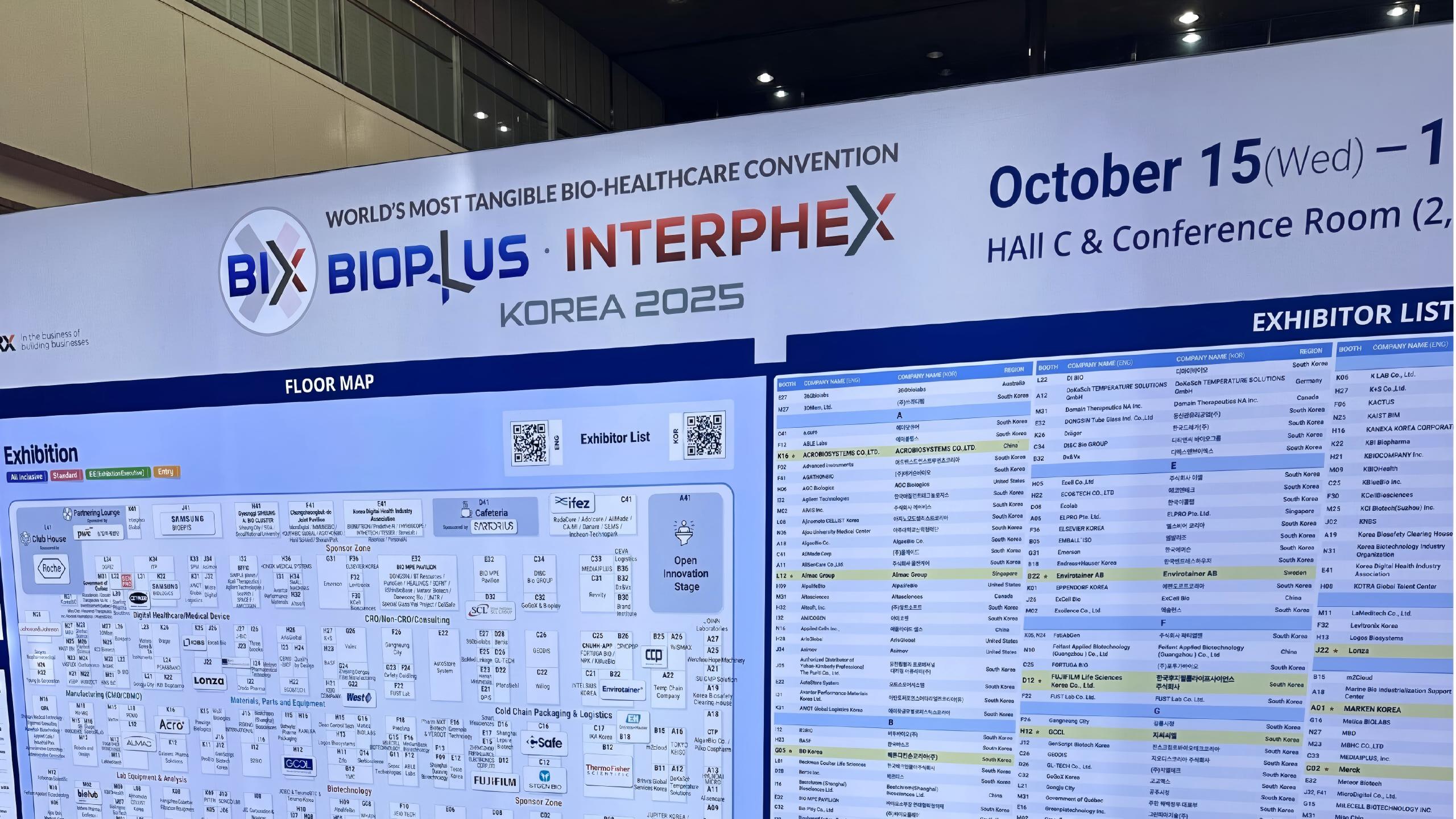

Seoul, Korea — November 2025 At BIOPLUS-INTERPHEX Korea 2025 (BIX 2025), Dongou MF showcased its advanced polymer-based microfiltration and solid–liquid