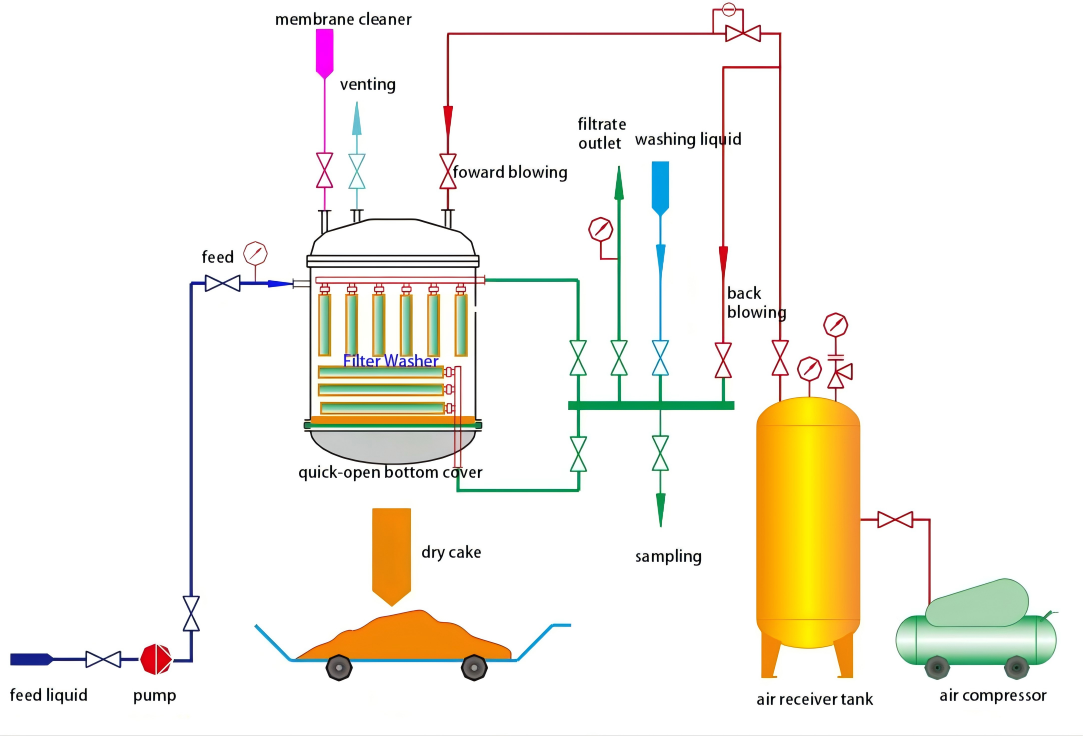

The PGH Filter-Press Washer is engineered for high solid-content slurry filtration and washing processes where low cake dryness is acceptable. With a sealed filter-press system and fully automated operation, it minimizes manual intervention while ensuring a clean and safe production environment. The PGH model is widely applied in fine chemicals, pharmaceuticals, food processing, and environmental industries, delivering reliable performance in combined slurry washing and clarification.

Fully enclosed operation ensures a cleaner and safer production environment.

Automatic cover-opening and pneumatic discharge reduce manual handling while improving safety.

Enables continuous production and higher workflow efficiency for large-scale slurry washing and clarification.

Single unit up to 500 m², with optional auxiliary modules for additional throughput.

Wetted parts available in plastic lining, stainless steel, or titanium to suit different chemical slurries.

Slurry clarification with acceptable wet cake: Ideal where filtrate clarity is the main requirement, including activated carbon decolorization and bulk chemical washing.

Consistent batch quality: Auxiliary filtration zones capture residual liquor, ensuring each batch is discharged without cross-contamination.

Continuous large-volume operation: Multi-unit synchronization supports high-throughput industrial processes, reducing downtime in chemical, food, and environmental industries.

Efficient crystal and fine particle handling: Maintains suspension stability while filtering impurities, especially effective for crystalline solution clarification and fine powders.

Proven industrial reliability: Extensively applied in fine chemicals, pharmaceuticals, food additives, and wastewater treatment, where clarified filtrate and stable throughput are critical.

| Model | PGH-1 | PGH-2 | PGH-3 | PGH-5 | PGH-10 | PGH-20 | PGH-30 | PGH-40 | PGH-60 | PGH-100 |

| Filtration Area (m²) | 1 | 2 | 3 | 5 | 10 | 20 | 30 | 40 | 60 | 100 |

| Capacity (t/h) | Determined from experimental data of the specific slurry | |||||||||

| Operating Pressure (MPa) | ≤0.25 | |||||||||

| Operating Temperature (°C) | ≤100 | |||||||||

| Vessel Diameter (mm) | φ300 | φ300 | φ400 | φ550 | φ800 | φ900 | φ1200 / φ1000 | φ1400 / φ1500 | φ1600 / φ1400 | φ2000 |

| Vessel Height (mm) | 1730 | 2030 | 2500 | 2530 | 3050 | 3440 | 3840 / 2480 | 4100 / 3800 | 4880 | 5330 |

| Inlet / Outlet (mm) | DN25/DN25 | DN40/DN40 | DN40/DN40 | DN40/DN50 | DN50/DN65 | DN65/DN65 | DN50/DN65 | DN65/DN65 | DN65/DN65 | DN80/DN80 |

| Discharge Port (mm) | φ300 | φ300 | φ400 | φ550 | φ800 | φ800 | φ1200 / φ1000 | φ1400 / φ1000 | φ1600 / φ1400 | φ1400 / φ1600 |

| Vessel Volume (m³) | ≤0.1 | 0.079 | 0.17 | 0.321 | 0.86 | 1.25 | 2.38 / 1.38 | 2.8 / 2.4 | 5.6 | 13.3 |

Dongou MF participated in the 23rd Pharma Asia 2025, held from December 2–4 in Karachi, Pakistan—Asia’s major exhibitions for pharmaceutical

KHIMIA 2025 brought together companies from across the global chemical and process industries, and DongouMF was pleased to participate in

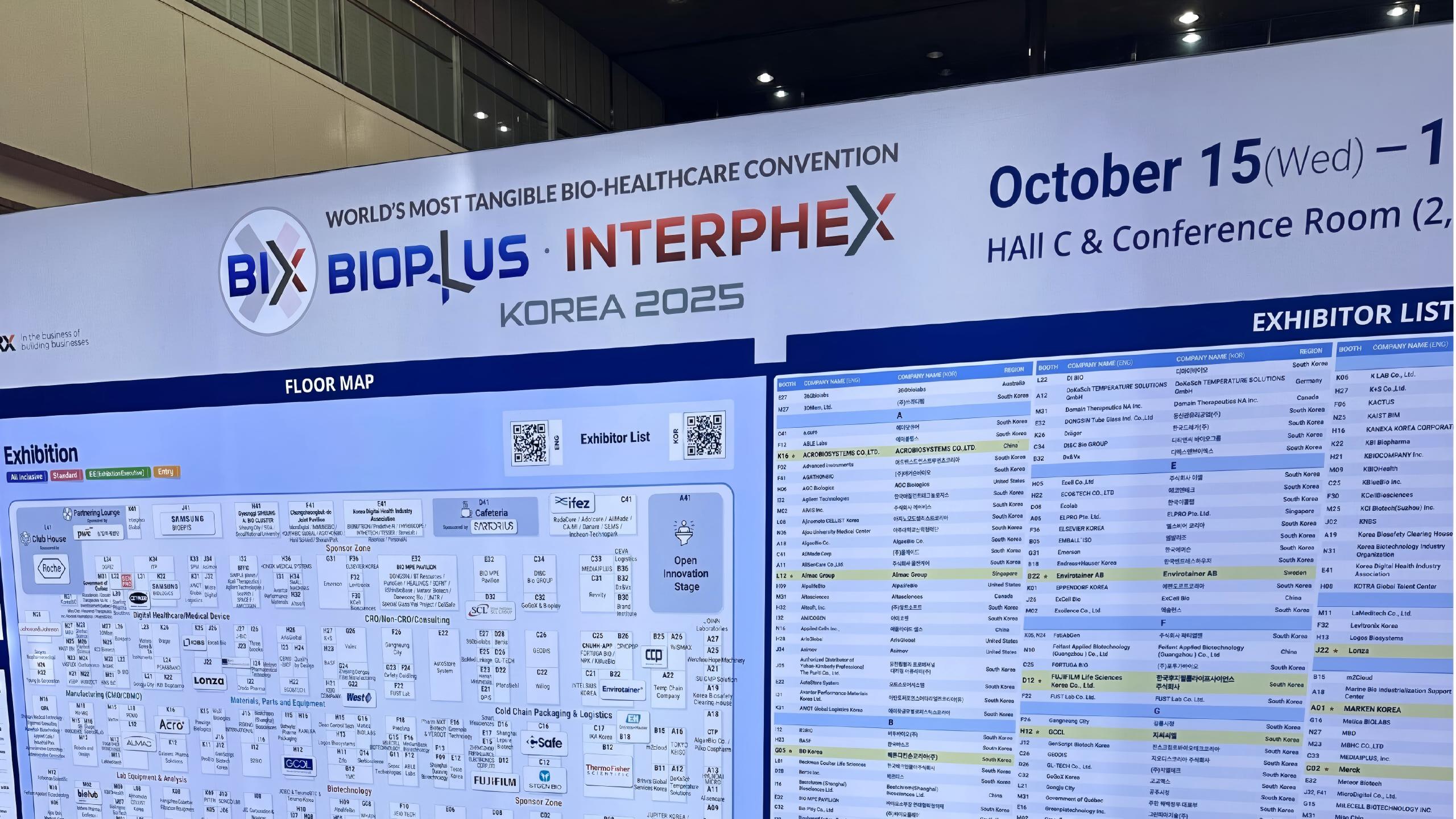

Seoul, Korea — November 2025 At BIOPLUS-INTERPHEX Korea 2025 (BIX 2025), Dongou MF showcased its advanced polymer-based microfiltration and solid–liquid