The PGT Horizontal Filter-Press Washer is designed for large-volume precision clarification and solid-liquid separation. With a horizontal, low-height structure and quick-opening mechanism, it can directly replace traditional plate-and-frame filter presses in existing plants, requiring no additional civil modifications. The system integrates filtration, washing, and pressure drying in one closed unit, reducing contamination risks and energy consumption while ensuring clean and efficient production. It has been successfully applied in metal powders, inorganic salts, crystalline products, and rare earth processing.

Requires less installation height, making it suitable for traditional plants as a replacement for filter presses.

Main filter tube section for rapid slurry filtration, plus auxiliary bottom filter plate for complete residue capture.

Combines filtration, slurry washing, and pressure drying in one sealed system, preventing cake contamination.

Enables fast disassembly, convenient maintenance, and efficient cake discharge.

Bottom filter plate area is 20% larger than comparable vertical models, delivering higher throughput per cycle.

Wetted parts available in plastic lining, stainless steel, or titanium to meet corrosion resistance requirements.

Closed filtration, back-flushing, chemical regeneration, and multi-unit synchronization.

Dongou MF participated in the 23rd Pharma Asia 2025, held from December 2–4 in Karachi, Pakistan—Asia’s major exhibitions for pharmaceutical

KHIMIA 2025 brought together companies from across the global chemical and process industries, and DongouMF was pleased to participate in

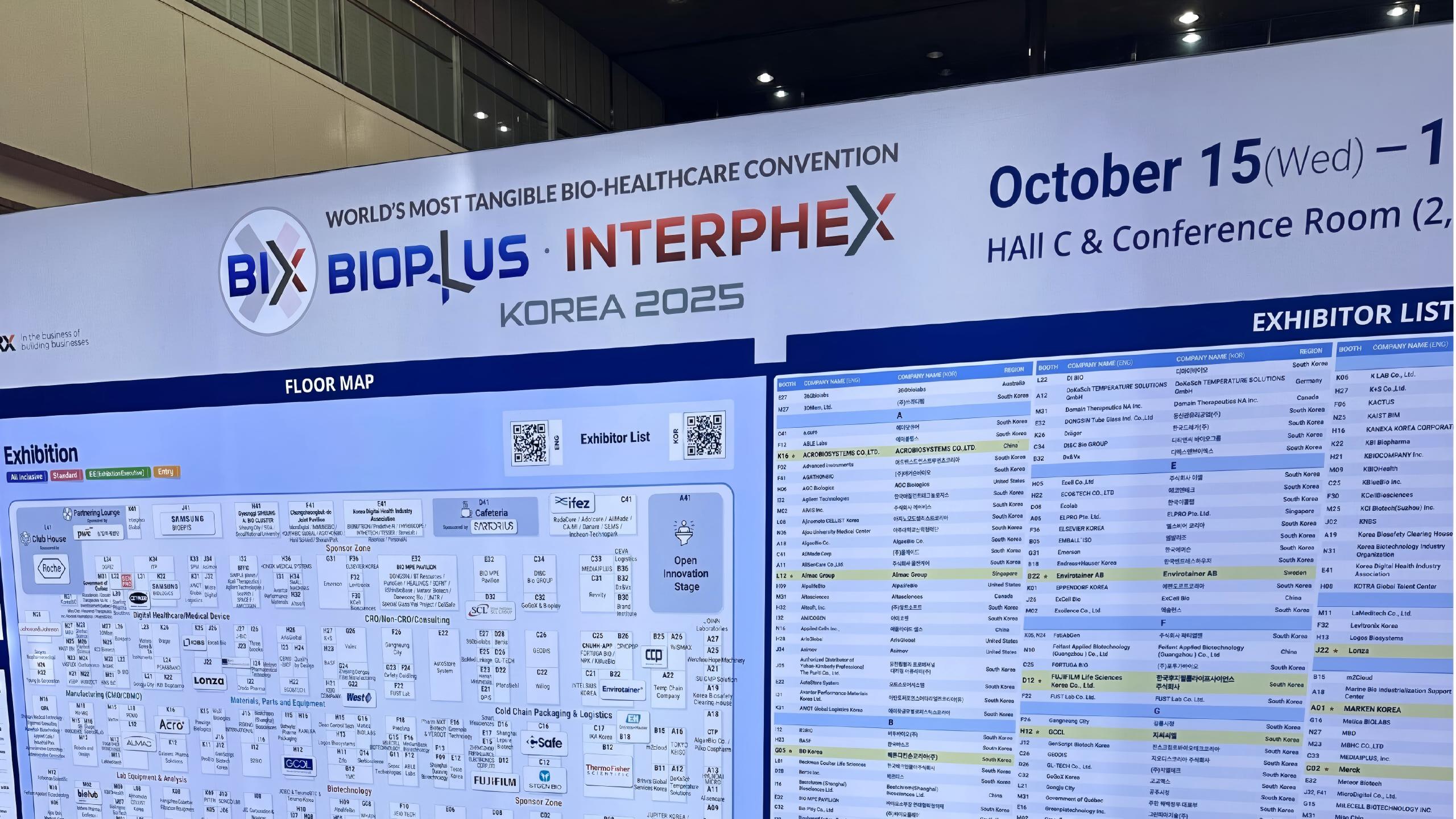

Seoul, Korea — November 2025 At BIOPLUS-INTERPHEX Korea 2025 (BIX 2025), Dongou MF showcased its advanced polymer-based microfiltration and solid–liquid